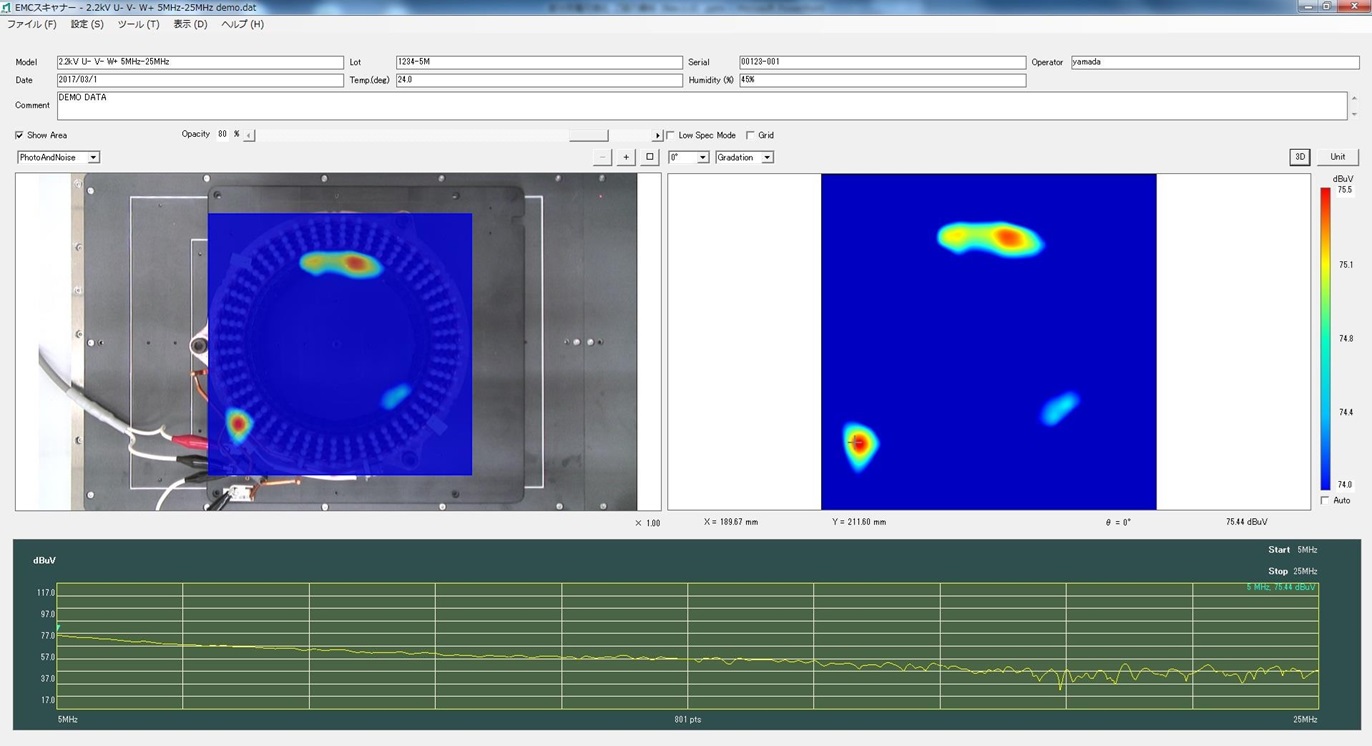

The electromagnetic waves caused by the partial discharge that occurs when high voltage is applied in the impulse winding tester are detected, the location of the discharge is identified and visualized, and the next intensity map is superimposed on a photograph.

➣Objective

- Pinpoint detection of coil insulation defects in motors, transformers, etc.

- Improved yield and post-market reliability by pursuing the cause of insulation defects(Failure rate reduction)

- Provide data that contributes to an increase in PD generated voltage

- Use of sic inverters contributes to higher inverter efficiency due to higher SW speed

- Visualization of discharge points in the mold module of IGBT and SIC inverters

We can contribute to the development of FMC countermeasures for inverter modules and prototypes of high surge resistant coils, speed up failure analysis, improve performance and reliability, and increase yield by improving processes.

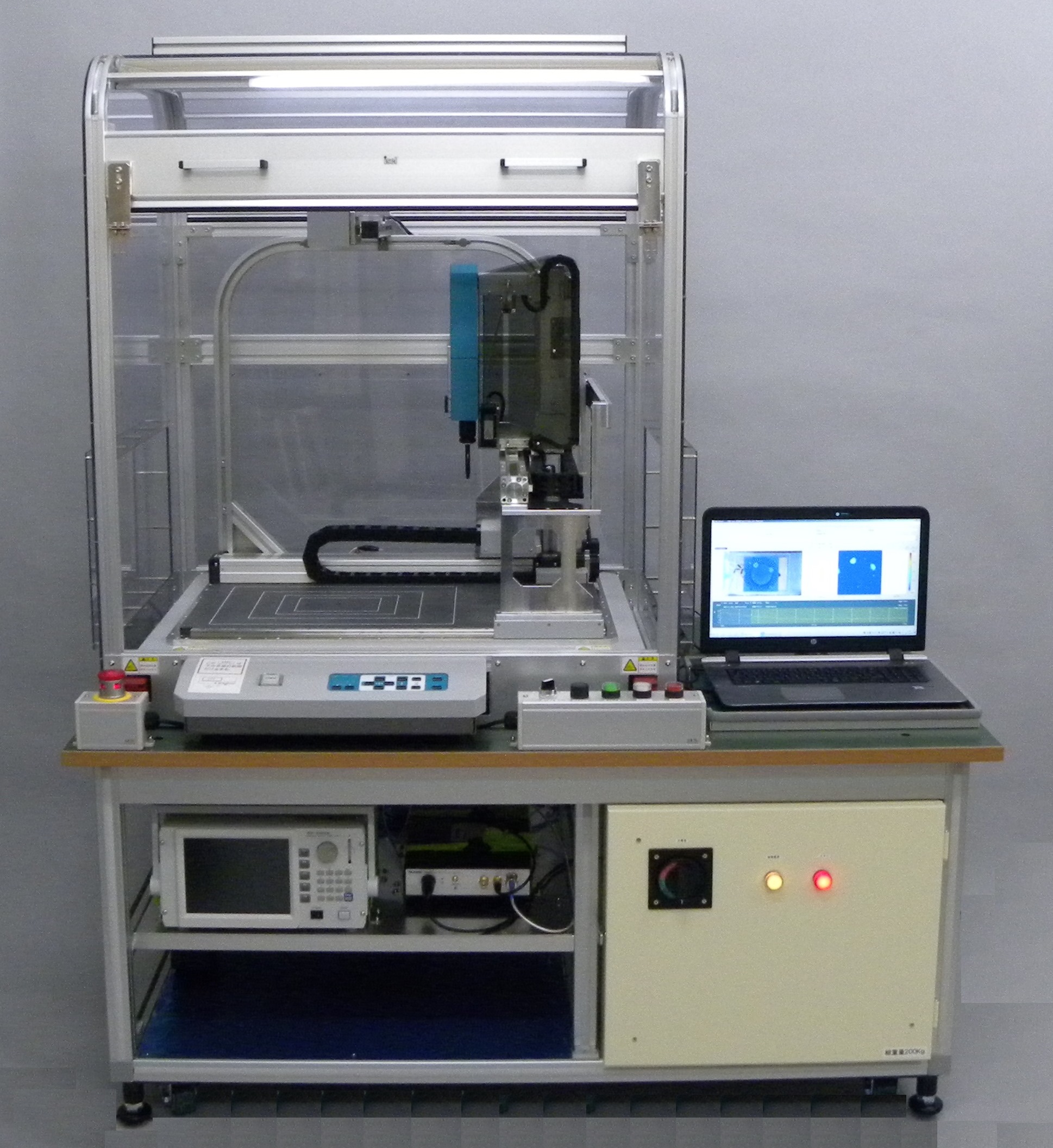

Partial Discharge Visualization System WM7700 Main system Componets

➣WM7700 Series High Perfomansce EMC Noise Scanners

- WM7300(A3size) Height 200mm(option 250mm)

- WM7400(A4size) Height 100mm

➣DWX-5PD-VI Impules partial discharge winding tester

- WM7700-compatible option

- Made by Electronic Control international, Inc.

➣RSA603A Real-time spectrum analyzer

- Manufactured by Tektronix, Inc.